SPECIALISTS IN LEAN MANUFACTURING

ABOUT LEAN MANUFACTURING

Soluciones de Lean manufacturing. Metodología que tiene como objetivo eliminar los

desperdicios y mejorar la eficiencia en los procesos de fabricación. Técnicas claves utilizadas en Lean Maufacturing en la producción ajustada, incluyen la producción de flujo continuo, los

sistemas kanban, la organización del lugar de trabajo en 5S, la producción justo a

tiempo (JIT) y el mantenimiento productivo total (TPM).

lean manufacturing

CATEGORIES

Trolleys

Customised tubular structures, enabling more efficient, faster and less wasteful production.

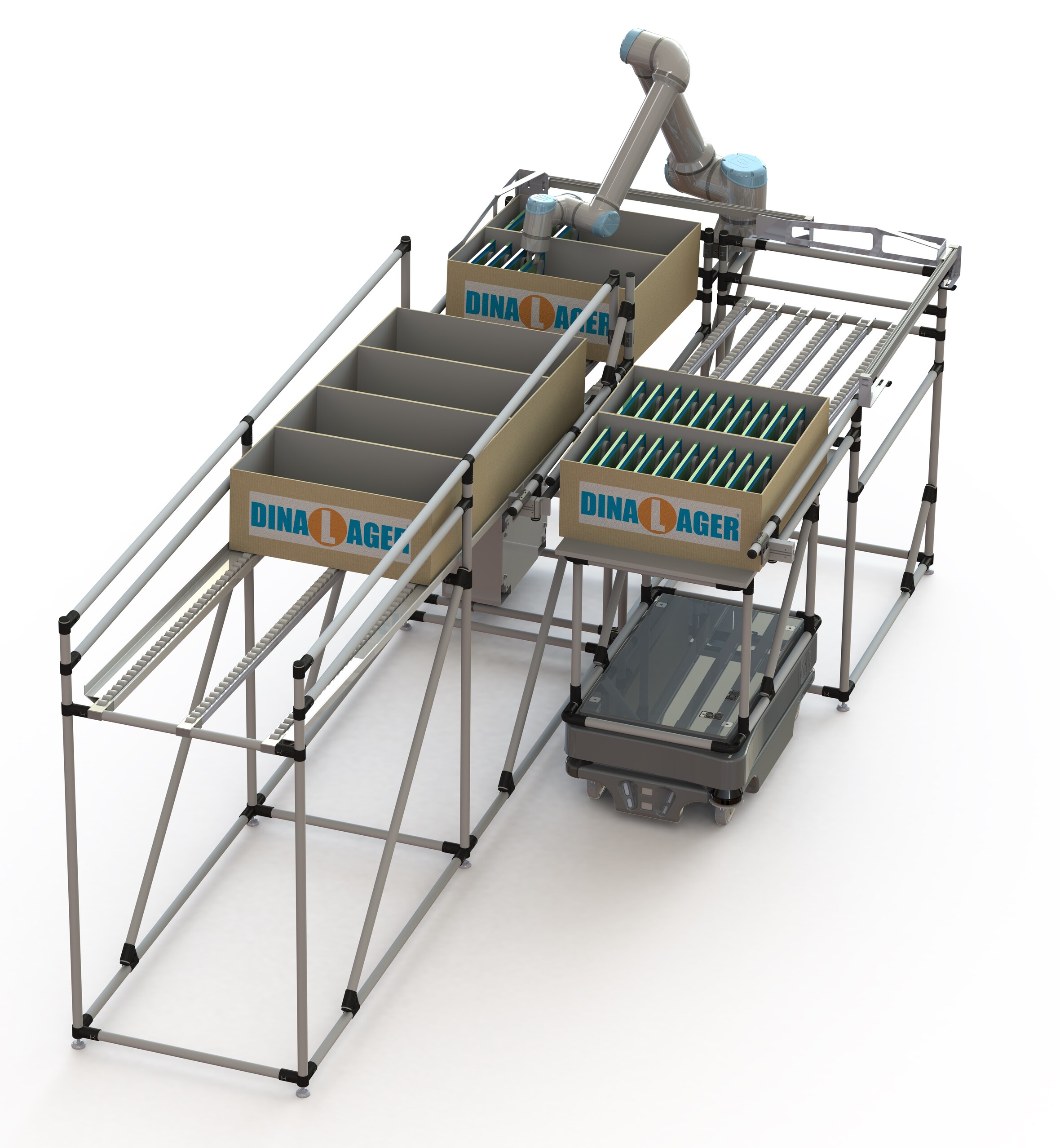

Semi Aumtomatisations

Combining customised tubular structures and lean manufacturing with semi-automation can be an effective strategy to improve efficiency during production processes.

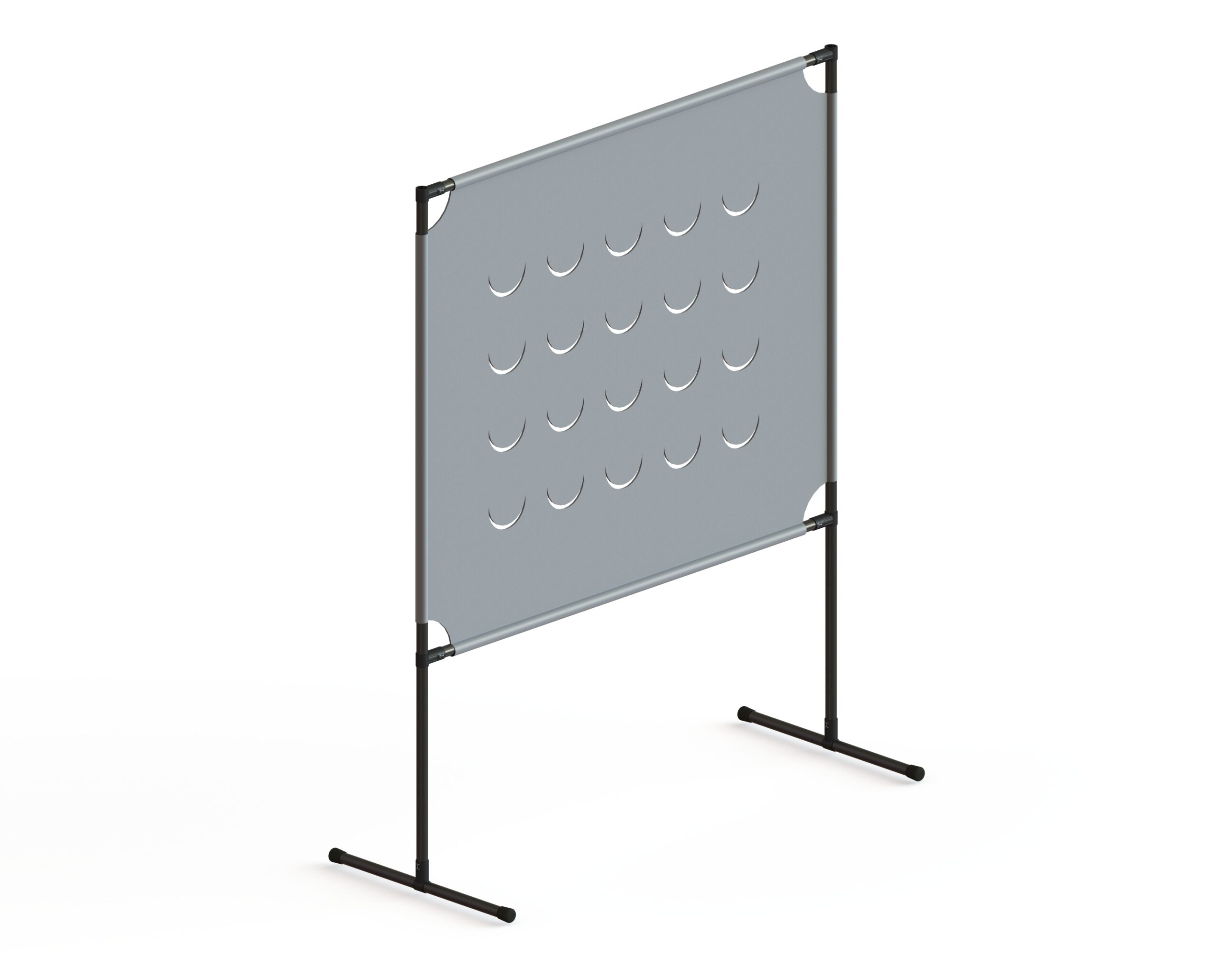

Structures for Visual Management

Structural developments for clear and fast visual management of communication and information, helping to improve efficiency and productivity.

Tables

Customised -tubular- structures, which provide more efficient, faster production with a lower error rate and lower cost.

Shelving

Customised and adapted -tubular- racks, which help to improve the efficiency of the manufacturing and stocking process.